2014 GLASS VAS 150L

2014 GLASS VAS 150L

Location:Бонн, Германия

Description

VAS 150Liter

as new condition = purchased in 2014 and has rarely been used

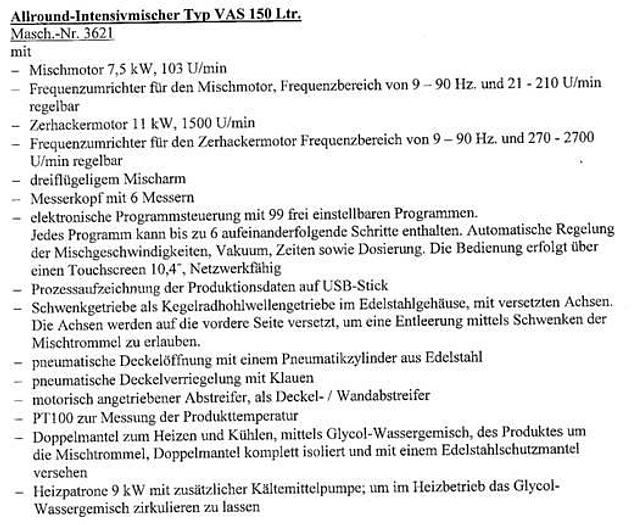

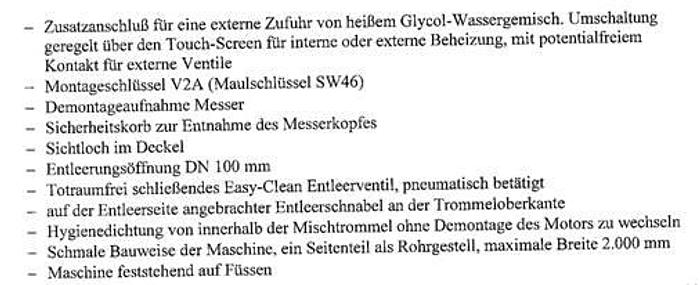

The Allround Intensive Mixer is a universal machine for mixing, batching, crushing, cuttering and emulsifying a wide variety of products. The products to be mixed can be dry, moist, pasty or liquid. The mixing paddle at the bottom moves the mixed product towards the wall. The product is moved upwards, forms a thrombe and collapses again in the middle. A high-speed motor is mounted on the side of the drum. Various crushing tools such as a U-shaped chopper, a knife head with 6 knives or a turbine can be attached here. The mixing blade at the bottom can be operated alone to produce a mixture of all components. In addition, the side motor with the crushing tool can be added for emulsifying, crushing or chopping. Feeding takes place with the lid open, or through feed lines in the lid or in the drum wall. All machines are manufactured by us in stainless steel according to the latest technology and hygiene standards. Each machine is manufactured according to your individual needs. To convince you of the quality and functionality of our machines, we can also offer you a demonstration with your products. Hygienic construction of our machines: The sealing system between the motor and the mixing tool is a hygienic seal. Easy to remove and clean, change or replace In all components and housings, water drains off without leaving residues during cleaning; hygienic surfaces are the result. When equipped with vacuum, the hoses for cleaning are equipped with BEST-CONNECT connections. This allows cleaning to be carried out in a very short time with a small amount of water. The machine housings may also be cleaned on the inside. Electrical safety: The operating elements are installed in every machine with at least IP65 splash-proof protection. The electrical system is always installed in an additional control cabinet in the side panel. To protect against moisture, a control cabinet heater and, depending on the equipment, ventilation are integrated. The electrical equipment complies with the latest legal regulations of the EU. Installation and maintenance: The machine is delivered as "plug and work" as far as possible. The covers of the housings can be opened without special tools. This gives you the greatest possible access to the individual assemblies. For easy access during maintenance, the components are clearly arranged and easy to reach. Technical details: All technical components within the machine are from German international market leaders. Thus, all parts are available worldwide. Depending on the equipment, we use components from the following manufacturers: ⦁ Control B&R, Siemens ⦁ Geared motors make SEW ⦁ Frequency converters make SEW ⦁ Electrics make Eaton ⦁ Pneumatics make Festo ⦁ Steam make Spirax Sarco ⦁ Measurement technology Endress+Hauser, Bürkert ⦁ Process valves Gemü, Bürkert ⦁ Load cells Minebea Intec ⦁ Sensor technology Pepperl & Fuchs, Sick, Euchner All components are also possible according to their specifications Spare parts: We provide you with a spare parts supply for all spare parts for a period of 10 years. We can manufacture and supply mechanical spare parts from our own production over the entire lifetime of a machine. Quality management: ⦁ GLASS is ISO 9001/2015 certified.

Find more here - https://www.ucymachines.com/

Specifications

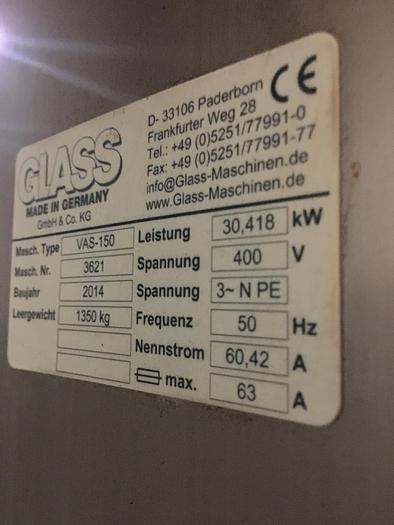

| Manufacturer | GLASS |

| Model | VAS 150L |

| Year | 2014 |

| Condition | Used |