2001 gelomat small Ice cream factory plant

Indisponible

2001 gelomat small Ice cream factory plant

Adresse:Hambourg, Allemagne

Description

Structure

Réservoir d'alimentation 100L (avec enveloppe chauffante)

Chauffage à 80°C

Agitateur inclus

produit pompe

homogénéisateur 300-400l/heure

Refroidisseur

L'unité de cuisson est intéressante pour les grands glaciers/productions. Actuellement l'usine produit 45l de batch,

(environ 10 heures par jour).

1a. Séquence de cuisson avec nettoyage

- Selon le cahier des charges du protocole de développement F11, la recette et le grammage, les ingrédients sont mis

ensemble.

- Mélanger les ingrédients liquides ensemble. Ajouter séparément la graisse végétale et le sirop de glucose au min. 30°C. Allumer l'agitateur

(vitesse 6-8) et le chauffage sur l'armoire de commande.

- A 50°C, tous les ingrédients secs peuvent être mélangés. Enfin, ajouter les liants.

- 45l par bouillie (env. 10 bouillies par jour).

- A 78°C, éteignez le chauffage et éteignez l'agitateur. Ouvrez le couvercle et le robinet de vidange. Ventilez la gamme de produits.

- Positionner le robinet by-pass de l'Homo en position horizontale.

- Ouvrir les conduites d'alimentation et de retour d'eau glacée ainsi que l'eau de refroidissement de l'homogénéisateur.

- Maintenant, la pompe mélangeuse et l'homogénéisateur peuvent être démarrés. Régler l'homogénéisateur à 180 bar.

- Le mélange est maintenant refroidi à 5-8°C et placé dans un seau désinfecté.

- Après env. 2-3 minutes, le mélange arrive au seau. Le seau est recouvert d'un sac en plastique et étiqueté.

- Lorsque le seau d'alimentation est vide, éteignez l'homo, la pompe de produit et l'eau glacée.

- Pour les produits très visqueux, un nettoyage intermédiaire doit être effectué dans tous les cas.

- Le mélange est temporairement stocké en chambre froide (6°C) ou surgelé à -18°C.

- Avant d'utiliser le mélange, un échantillon est prélevé pour le laboratoire et testé pour les ingrédients.

1b. Nettoyage de l'installation de cuisson

- Doser l'eau dans le réservoir d'alimentation (100l).

- Ajuster à 1,0 % de concentration caustique avec 1 litre de solution d'hydroxyde de sodium.

- Allumez l'agitateur et le réchauffeur. Chauffez ensuite la lessive à 78°C et nettoyez pendant 30 minutes. Nettoyer le couvercle du récipient

manuellement.

- Acidifier le système une fois par semaine avec de l'acide nitrique ( 70°C). Concentration 1% = 1l d'acide nitrique. Acidifier pendant 30 minutes.

- Ouvrir les clapets manuels et démarrer l'homogénéisateur et la pompe de produit. Faire circuler la lessive pendant 60 min.

- Ensuite, rincez la plante avec de l'eau.

- Effectuer et documenter un contrôle de nettoyage.

En savoir plus ici - https://www.ucymachines.com/

Caractéristiques

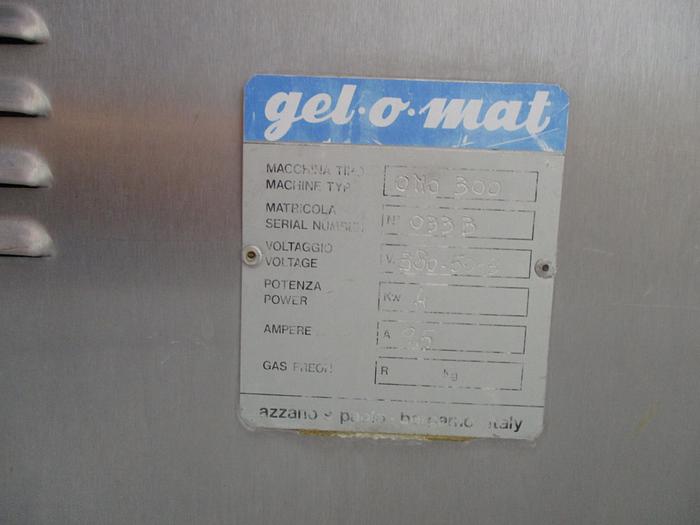

| Fabricant | gelomat |

| Modèle | small Ice cream factory plant |

| Année | 2001 |

| Condition | utilisé |