2007 Heller 1809 MKIII

2007 Heller 1809 MKIII

Plaats:Oslo, Noorwegen

Beschrijving

Heller 1809 MKIII Reflow Oven 2005

Description,

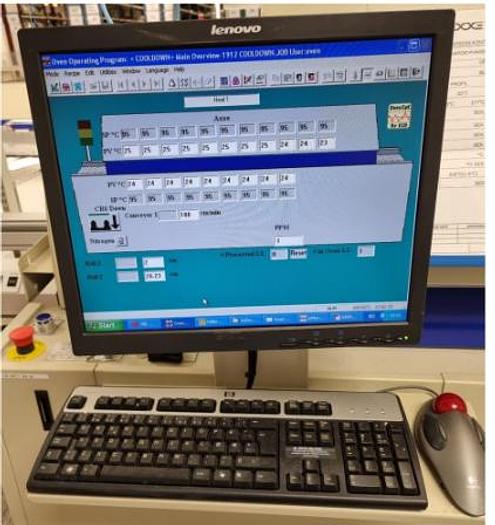

Windows XP Operative System

Min/max PCB width 5- 457mm

Center Board Support

Chain drive

Chain lubrication system

Internal cooling system

N2 on /off by software

Board drop sensor

Board counter

KIC Profiler / ECD Profiler

The Heller 1809 MKIII is a reflow soldering oven designed for surface-mount technology (SMT) processes in electronics manufacturing. Here are some key features you might expect from a 2005 model:

Soldering Technology: The Heller 1809 MKIII is likely to use either infrared (IR) or convection heating methods for reflow soldering. Infrared heating is suitable for lead-free soldering processes, while convection provides more uniform heating across the board.

Zone Configuration: It probably consists of multiple heating zones, typically three to seven, with individual temperature controls. Each zone will have different temperature profiles to optimize soldering for different components and assemblies.

Transport System: The reflow oven likely features a conveyor belt system to carry the PCBs (Printed Circuit Boards) through the heating zones. The conveyor speed can usually be adjusted to control the soldering time.

Cooling Zone: Following the heating zones, there should be a cooling zone to gradually reduce the temperature of the soldered PCBs, preventing thermal shock to the components.

Software Control: The reflow oven may be equipped with a user-friendly interface to set and monitor temperature profiles, conveyor speed, and other parameters.

Safety Features: Modern reflow ovens often come with safety features like over-temperature protection and emergency stop buttons to ensure safe operation.

Find more here - https://www.ucymachines.com/

Contact us at - sales@ucymachines.com

Specificaties

| Fabrikant | Heller |

| Model | 1809 MKIII |

| Jaar | 2007 |

| Conditie | Gebruikt |