Finetech Electronic 294 FPL-J

Non disponibile

Finetech Electronic 294 FPL-J

Posizione:Saarbrücken, Germania

Descrizione

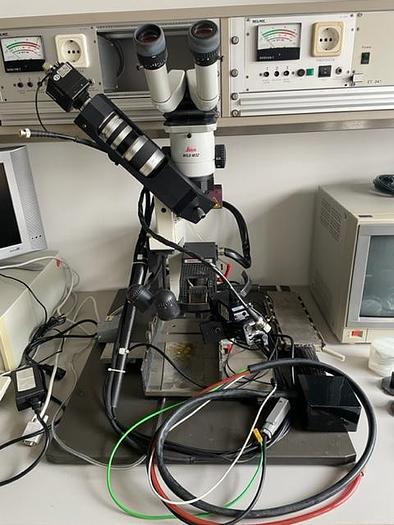

Un sistema di microsaldatura BGA della serie "Fineplacer 294 FPL-J" del produttore berlinese Finetech Electronic GmbH

& Co.KG.

L'unità di saldatura è composta da un modulo della testa di saldatura con una bombola di azoto comprensiva di raccordi e tubi flessibili vari. Esso

è completato, tra le altre cose, da uno stereomicroscopio Leica per il posizionamento preciso dei componenti con Leica Wild M3Z

ottica, un sistema video girevole Watec per il monitoraggio e l'ispezione del processo di saldatura con uno schermo di controllo Panasonic e

un supporto per PCB dotato di superficie subacquea.

Infine, il tavolo di lavoro personalizzato offre diversi dispositivi di controllo e monitoraggio adattati al processo di saldatura

un'unità informatica CD-ROM comprendente un monitor. Sono disponibili documentazione e istruzioni operative, nonché saldature

teste e pipette.

Fineplacer 294 FPL-J è un modello specifico di macchina bonder ad alta precisione prodotta da Finetech. Legatori di stampi

sono utilizzati nell'industria dei semiconduttori e della microelettronica per collegare minuscoli componenti elettronici (come quelli integrati

circuiti o chip semiconduttori) su substrati o circuiti stampati (PCB) con estrema precisione. Questo processo è

essenziale per l'assemblaggio di dispositivi a semiconduttore e pacchetti microelettronici.

Ecco alcune caratteristiche e capacità chiave del Fineplacer 294 FPL-J:

1. Alta precisione: Fineplacer 294 FPL-J è progettato per l'incollaggio di matrici ad alta precisione, con precisione micrometrica

gamma, garantendo che i componenti elettronici siano posizionati accuratamente sul substrato.

2. Opzioni di incollaggio flessibili: offre flessibilità in termini di tipi di incollaggi che può creare, inclusi epossidici,

legami eutettici e flip-chip, per soddisfare diverse esigenze di assemblaggio.

3. Incollaggio multicomponente: la macchina può gestire l'incollaggio di più componenti su un unico substrato, rendendolo

adatto per assemblaggi complessi.

4. Riscaldamento del substrato e controllo della temperatura: alcuni modelli possono includere funzionalità di controllo della temperatura per garantirne il corretto funzionamento

incollaggio, soprattutto per incollaggio eutettico.

5. Software intuitivo: spesso include software intuitivo per una facile programmazione e configurazione.

6. Ispezione in linea: la macchina può essere dotata di sistemi di ispezione in linea per garantire la qualità e la consistenza dell'incollaggio.

7. Tecniche di incollaggio versatili: supporta varie tecniche di incollaggio, incluso l'incollaggio a termocompressione e

incollaggio ad ultrasuoni.

8. Manipolazione con il vuoto: un sistema di movimentazione con il vuoto viene generalmente utilizzato per prelevare e posizionare in modo sicuro i componenti durante l'incollaggio

processi.

Scopri di più qui - https://www.ucymachines.com/ [https://www.ucymachines.com/]

Contattaci a - sales@ucymachines.com

Specifiche

| Produttore | Finetech Electronic |

| Modello | 294 FPL-J |

| Condizione | usato |