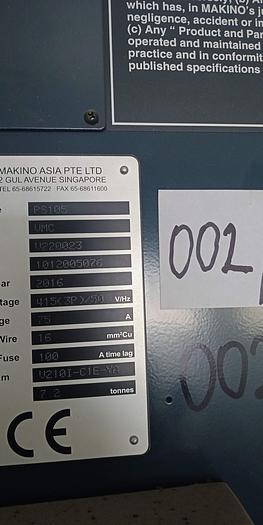

2016 Makino PS 105

2016 Makino PS 105

Local:Bratislava, Eslováquia

Descrição

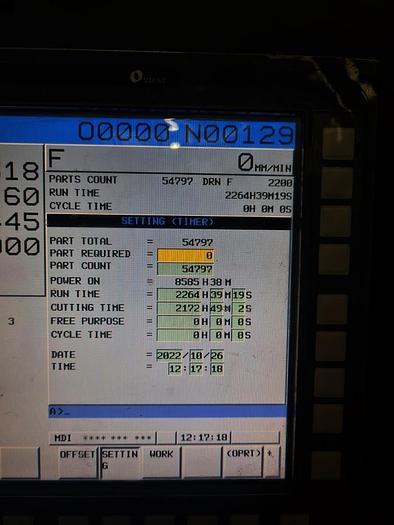

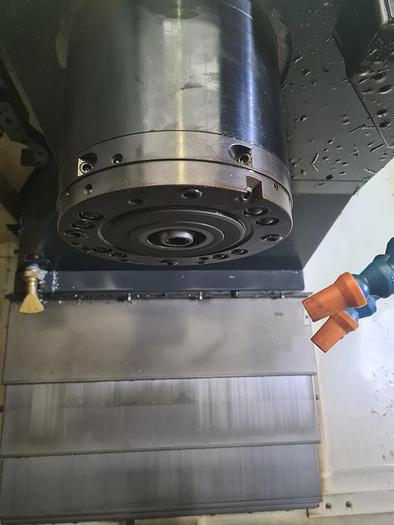

- Machining center MAKINO, type PS 105 see picture for hours

Technical parameters of the machine:

Table: 1300 x 510 mm X: 1050 mm Y: 510 mm Z: 460 mm

spindle speed 14.000 rpm

spindle support HSK-A63

rapid traverse X axis - 48.000 mm/min, Y and Z axis - 36.000 mm/min

cutting feed rate - 30.000 mm/min

load capacity - 800 kg

Tool magazine - ATC capacity: 30 tools (60 opt)

tool weight - 8 kg

The Makino PS 105 machining center is a high-performance vertical machining center (VMC) designed for precision machining applications. It is part of Makino's Professional Series, which offers advanced technologies and features for high-speed machining and superior accuracy.

Here are some details about the Makino PS 105 machining center:

- Spindle and Cutting Performance:

- The PS 105 is equipped with a 12,000 RPM spindle that delivers up to 30 horsepower and 95.5 Nm of torque, making it capable of handling a wide range of materials including steel, aluminum, and titanium. The spindle is designed for high-speed cutting and quick acceleration, which results in reduced cycle times and improved productivity.

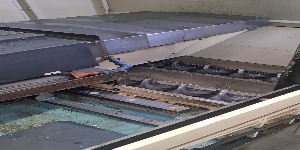

- Table Size and Capacity:

- The PS 105 features a large worktable that measures 1,100 mm x 600 mm (43.3" x 23.6"), with a maximum load capacity of 800 kg (1,763 lbs). The table has T-slots for flexible fixturing and can accommodate a wide range of workpiece sizes and shapes.

- Axis Travel and Accuracy:

- The PS 105 has a high-speed, high-precision linear guideway system that provides fast and accurate movement in the X, Y, and Z axes. The X-axis has a travel of 1,050 mm (41.3"), the Y-axis has a travel of 600 mm (23.6"), and the Z-axis has a travel of 560 mm (22.0"). The machine is also equipped with a thermal compensation system that ensures consistent accuracy throughout the machining process.

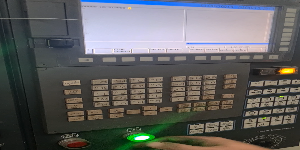

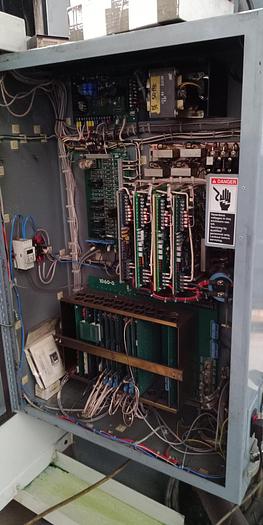

- Control System:

- The PS 105 is equipped with the Makino Professional 6 (Pro6) control system, which provides intuitive operation and advanced programming capabilities. The Pro6 control system features a large 19-inch touchscreen display and a user-friendly interface that simplifies programming and setup. The system also includes advanced features such as high-speed machining algorithms, tool breakage detection, and adaptive feedrate control.

- Automation and Connectivity:

- The PS 105 can be equipped with a range of automation options, including robotic part loading and unloading systems, pallet changers, and tool changers. The machine also features advanced connectivity options that allow it to be integrated with other machines and manufacturing systems, enabling seamless data transfer and real-time monitoring of production processes.

Overall, the Makino PS 105 machining center is a high-performance machine that offers advanced technologies and features for precision machining applications. Its robust construction, high-speed spindle, and advanced control system make it well-suited for a wide range of industries, including aerospace, automotive, and medical device manufacturing.

Here are the detailed specifications of the Makino PS 105 machining center:

Machine Dimensions:

- Length: 3,510 mm (138.2")

- Width: 2,460 mm (96.8")

- Height: 2,850 mm (112.2")

Machine Weight:

- Approx. 9,000 kg (19,842 lbs)

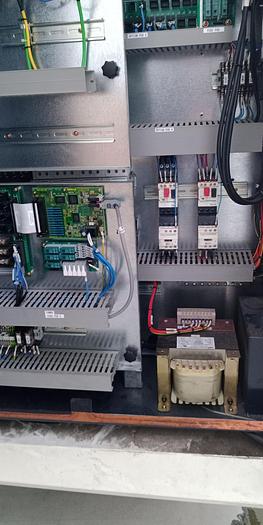

Power Requirements:

- 200-240 V, 3-phase, 50/60 Hz, 75 kVA (max)

These specifications may vary depending on the specific configuration of the machine.

Find more here - https://www.ucymachines.com/

Especificações

| Fabricante | Makino |

| Modelo | PS 105 |

| Ano | 2016 |

| Condição | Usado |