2002 Finetech Fineplacer 183

2002 Finetech Fineplacer 183

位置:柏林, 德国

描述

Rework-Station

Rework of components Finetech Compact Rework System FinePlacer, complete package.

Scope of delivery :

Finetech Fineplacer Rework Station Type: FPL-N 183-27

with:

- Modules for dynamic control of upper and lower heat

- XY table with control module, Finetech vacuum tweezers, ambient lighting,

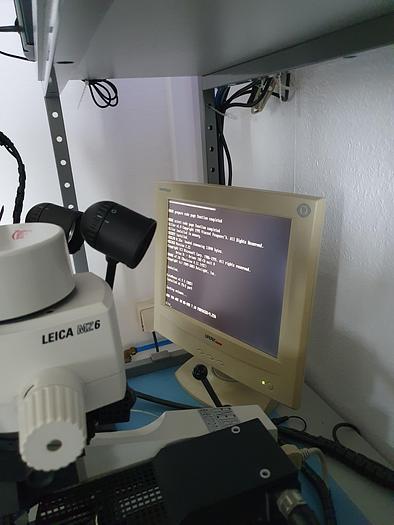

- Leica stereo microscope attachment MZ6 for fine positioning of components,

- 'MIRAGE' unit (image splitter) with camera for precise placement of large IC packages,

- second camera on all-round carousel for real-time observation of the soldering process,

G0uovyn

- Finetech 'Adjustment Set' for system calibration,

- 8 pieces of soldering heads (for BGAs, SOPs and QFPs),

- a SONY monitor for camera image display,

- 7 pieces of stencils with holders for selective solder paste printing, matching spatulas,

- 2 external temperature sensors for additional control of the, soldering process,

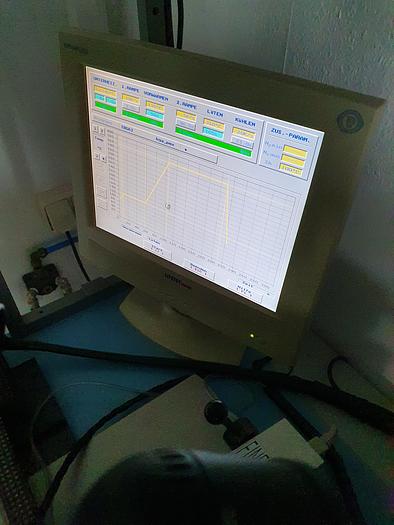

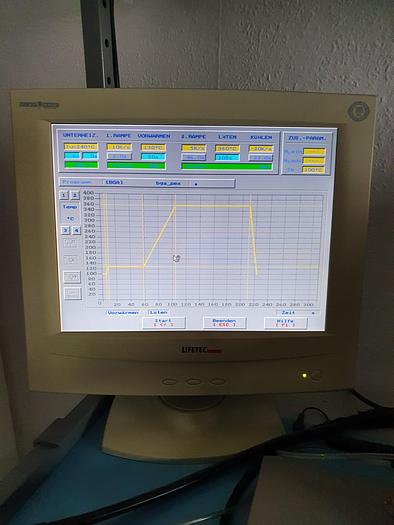

- Finetech documentation (several binders of operation and service documents), control software 'COMISS II', version 1.6 for MS-DOS,

- PC with Intel x86 Gen 6, 500 MB RAM, 4 GB hard disk, MS-DOS, LCD monitor,

- Schneider Medic Air 300-50 Silent compressor (encapsulated for sound reduction), 8 bar with 50 liter pressure vessel,

- refrigeration dryer unit BEKO RA3,

- numerous installation materials for compressed air piping (if needed, for self-dismantling).

Rework stations are used for repair or selective assembly of circuits in PLCC, QFP, SOP, BGA packages. It is also very suitable for the assembly of PCB prototypes, single pieces or small series. For the latter it was used in our company.

The "Fineplacer 183" from the market leader Finetech uses hot air in the leaded and lead-free soldering process. Equipped with an underheater to reduce distortion during soldering, the defective component is heated directly with a special top heater.

The user interface allows real-time process monitoring due to the real value display. All parameters - the heating gradient, peak temperature, top and bottom heating temperature - can be flexibly changed and saved as profiles for reuse. The heating gradient is freely adjustable between 1 and 50 K/s. The highest achievable temperatures are 380°C at the top heating and 360°C at the bottom heating.

If you come to Berlin you can get a full on training of the unit as well from the experienced owner.

The camera system or the Leica stereo microscope enable simultaneous viewing of the component underside with the surface of the PCB via the "split-field optics"(prism). With the aid of the work table sliding on an air cushion, an initial rough centering between the component and the PCB is achieved. Final centering is achieved with split-field optics and micrometer screws, allowing placement accuracy of less than 10μm.

System is connected and can be worked on, inspection and test is desired. Instruction can be obtained from us free of charge.

The year of manufacture of the station offered here is 2002 (original receipts in parts available), the compressor unit and the refrigeration dryer 2007 (purchase receipts available).

Two external temperature sensors can be connected to create new soldering profiles, allowing the soldering process to be checked live.

The rework unit can also be purchased separately (without the compressor and refrigeration dryer).A Medic Air Compressor and refrigeration dryer can be purchased in addition. Please check here for the listing https://www.ucymachines.com/

Find more here - https://www.ucymachines.com/

参数规格

| 制造商 | Finetech |

| 型号 | Fineplacer 183 |

| Year | 2002 |

| (使用) 状况 | 二手的 |