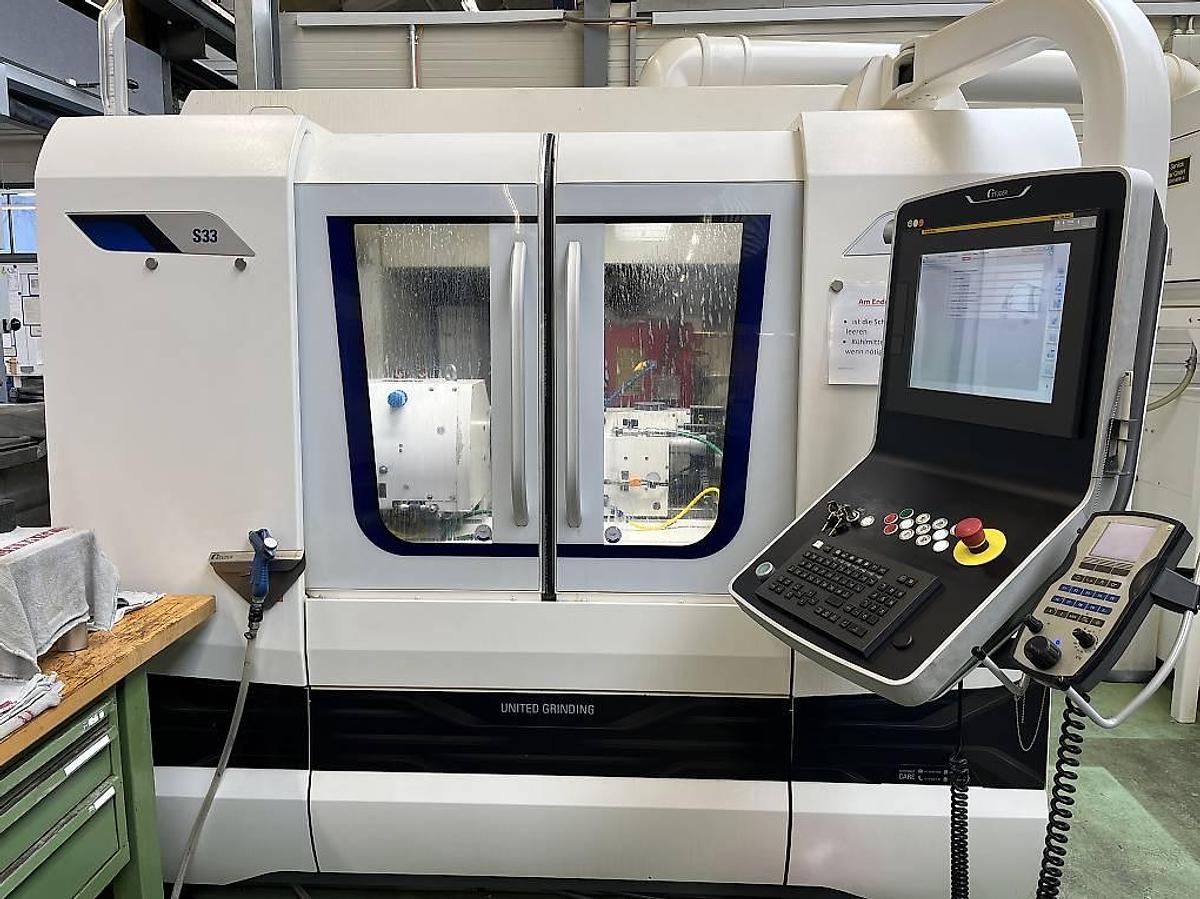

2022 STUDER S33_1045

2022 STUDER S33_1045

Contact us for price

Location:Switzerland

Description

Manufacturer:STUDER

Model: S33_1045

Year of Manufacture: 2022

Operating Hours : approx. 2500h

Included Equipment: DGS filter system.

Tip length : 400mm

with 2 grinding wheels

Core Machine Layout

- Capacity:

- Distance between centers: 400 mm.

- Center height: 175 mm.

- Axes:

- X1-Axis (Cross Slide): 370 mm travel; speed of 0.001–15,000 mm/min; absolute linear measuring system with 0.00001 mm resolution.

- Z1-Axis (Longitudinal Slide): 500 mm travel; speed of 0.001–20,000 mm/min; absolute linear measuring system with 0.00001 mm resolution.

- Machine Bed: Made of Granitan S103 with V and flat guideways and S200 sliding surfaces.

Grinding Wheelhead (H1)

- Configuration: Fixed wheelhead specifically for external grinding (Position T2 right).

- Swivel Range: Manually adjustable to $0^{\circ}$, $15^{\circ}$, or $30^{\circ}$ with pneumatic lifting for easy adjustment.

- Spindle: Belt-driven, 9 kW motor with frequency converter, enabling a constant cutting speed up to 50 m/s.

- Grinding Wheel Capacity: Designed for wheels up to $\varnothing 500 \times 80$ mm.

Workhead & Tailstock

- Universal Workhead: * Taper: MT 5 (MK 5) with a 30 mm spindle bore.

- Performance: 3 kW drive; speed range of 1–1500 rpm.

- Accuracy: Roundness accuracy during live spindle grinding of 0.0004 mm.

- Tailstock:

- Taper: MT 4 (MK 4) with 60 mm quill stroke.

- Adjustment: Manual fine adjustment for cylindricity correction of $\pm 0.08$ mm on the diameter.

Control & Automation

- CNC System: Fanuc 0i-TFP with a 15-inch color touch-screen and a portable PCU-Terminal II hand control.

- Software: Includes StuderWIN (Release F) with Pictogramming and Studer Technology integrated for automatic calculation of optimal grinding parameters.

- In-process Control: Equipped with TouchPositioning (TS 150 probe) for active longitudinal positioning and SBS electronic contact detection (AE sensor).

- Connectivity: B3 Profibus loader interface for automated workpiece changing and OPC-UA for operational data acquisition.

Find more here - https://www.ucymachines.com/

Contact us at - sales@ucymachines.com

Specifications

| Manufacturer | STUDER |

| Model | S33_1045 |

| Year | 2022 |

| Condition | Used |

| Stock Number | 757324 |