Complete Used Nonwoven Production Plant for Sale - Needlepunch Line with Fiber Opening, Carding, Lapping, Needling and Winding

Complete Used Nonwoven Production Plant for Sale - Needlepunch Line with Fiber Opening, Carding, Lapping, Needling and Winding

Contact us for price

Location:Frankfurt, Germany

Description

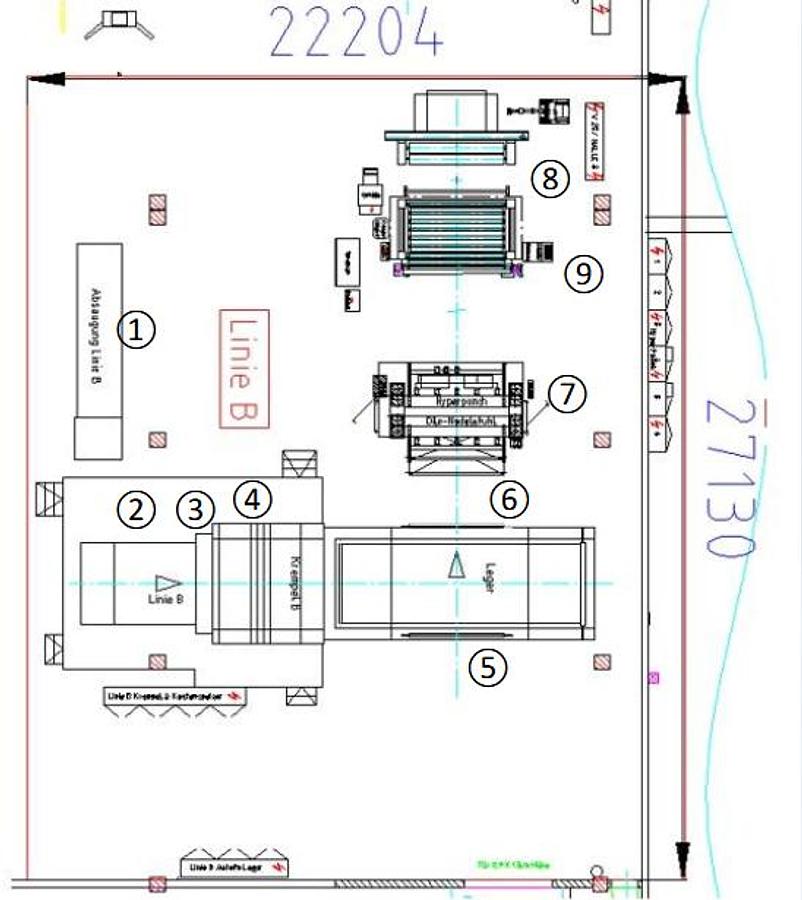

The plant consists of two production units: Production Line B and Pre-Mix Unit 5 (MA5).

PRODUCTION LINE B

Production Line B is a complete nonwoven needlepunch line consisting of the following components listed in process order.

1. Suction / Filter Station (Filterstation)

Function: Fiber dust extraction and air filtration for the production line.

2. Feed Shaft

Manufacturer: Spinnbau Bremen

Machine length: 3,970 mm

Machine width: 2,600 mm

Machine height: 6,233 mm

3. Belt Scale with Vibrating Shaft - Protec

Vibrating Shaft:

Length: 880 mm

Width: 2,800 mm

Height: 1,500 mm

Weight approx.: 870 kg

Belt Scale:

Length: 550 mm

Width: 3,000 mm

Height: 700 mm

Weight approx.: 550 kg

Power supply: 3NAC 400V 50Hz 20A

Description: The vibrating shaft produces a uniform fiber feed. The belt scale measures the weight of the fiber material being transported and regulates the feed speed of the downstream card accordingly.

4. Card

Manufacturer: Hergeth Hollingsworth

Year of manufacture: 1990

Control system renewed by Protec in 2016

Machine length: 4,210 mm

Machine width: 3,800 mm

Machine height: 2,500 mm

Machine weight approx.: 6,000 kg

Working width: 2,500 mm

Configuration:

Feed unit with electromagnetic safety clutch and 2 pairs of feed rollers, diameter 94 mm

Pre-opening unit with lowerable trough, 1 pre-roller diameter 413 mm, 1 pre-roller diameter 550 mm, 2 pairs worker/stripper rollers diameter 219/123 mm, 1 transfer roller diameter 550 mm

Main cylinder unit with 5 pairs worker/stripper rollers diameter 219/123 mm, 1 main cylinder diameter 1,500 mm

Doffer unit with 1 doffer diameter 850 mm and 1 set of crush rollers diameter 260 mm, web take-off via roller draw-off

Base frame height 700 mm

Fiber fly and dust extraction

Press roller diameter 2,500 mm

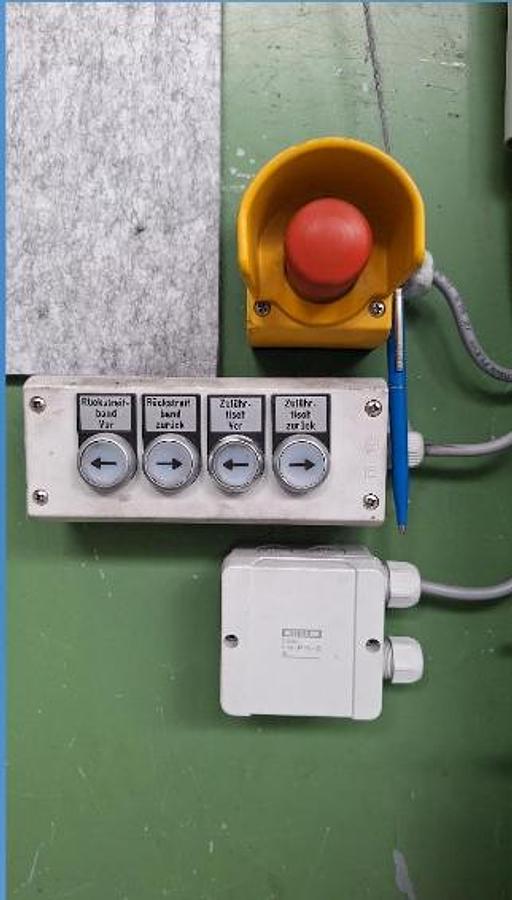

5. Cross-Lapper

Manufacturer: Autefa

Model: Topliner CL 4000/4002 and WebMax

Year of manufacture: 2006

CE conformity declaration available

Machine length: 3,815 mm

Machine width: 8,740 mm

Machine height: 2,165 mm

Topliner CL 4002 specifications:

Card working width: 2,500 mm

Maximum lapping width: 3,500 mm

Maximum web laying speed: 130 m/min

Take-off belt speed: 0 to 25 m/min

Lapper elevation: 100 mm

WebMax specifications:

Card working width: 2,500 mm

Description: The cross-lapper is designed for processing textile fibers including synthetic, natural, and regenerated fiber webs, as well as blends. Fiber fineness range greater than 0.7 dtex. Web weights achievable up to 5,000 g/m2 by multiple layering of the card web.

6. Web Drafting Unit (Streckwerk)

Machine length: 1,570 mm

Machine width: 3,640 mm

Machine height: 1,650 mm

Working width: 2,500 mm

Description: The web drafting unit re-orients cross-laid fibers partially into the machine direction, balancing longitudinal and transverse strength. It consists of three separately driven roller trios with saw-tooth wire clothing. As a special design, the unit is adapted to the rising web feed angle between the lapper exit and the needleloom entry.

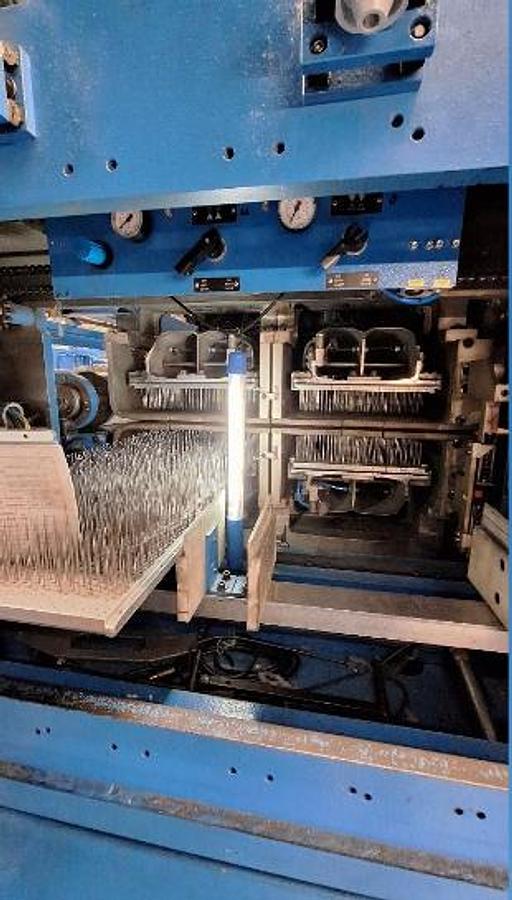

7. Double Needleloom

Manufacturer: Dilo

Type (upper beam): CBF 3, Number/Year: 9512/2006

Type (lower beam): DI-LOOM OUG-II HVSL 31, Number/Year: 9513/2006

Machine length: 3,340 mm

Machine width: 5,120 mm

Machine height: 4,475 mm

Machine weight: 38 t

Maximum working width: 3,100 mm

Maximum stroke frequency: 1,375 min-1

Needle beam stroke: 60 mm

Horizontal beam stroke: 0 to 6 mm

Number of needles: approx. 15,428 per 1 m working width

Main drive: 75 kW

Control panel: Siemens Simatic MP270

Description: Special high-performance needleloom with elliptical needle beam kinematics. Installed on vibration isolators without foundation. Needling from both top and bottom via 2 needle boards each, alternating or simultaneous. Needle beams move vertically and horizontally. Pneumatic clutch for rapid switching between alternating and simultaneous needling, and for decoupling the lower needling unit. Needle beams are aluminum special profiles with high bending and torsional stiffness, with quick-clamping system for rapid needle board changes.

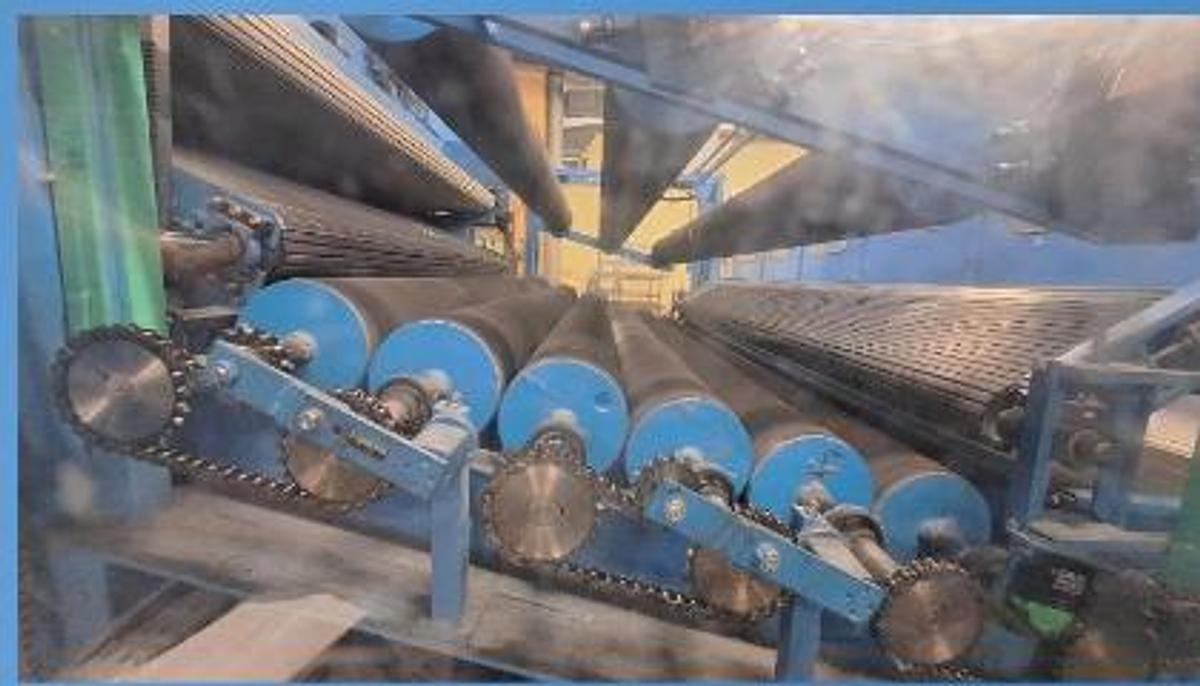

8. Machine Outfeed: Goods Storage, Slitter, and Winder

Goods Storage Unit - Suchy WOB 3200:

Manufacturer: Suchy

Storage capacity: 40 m

CE conformity declaration available

Machine width: 4,300 mm

Machine length: 5,010 mm

Machine height: 5,270 mm

Minimum working width: 1,000 mm

Maximum working width: 3,000 mm

Roller top width: 3,200 mm

Fabric weight range: 50 to 2,000 g/m2

Working speed: 3 to 40 m/min

Production speed: 20 m/min

Compressed air connection: 6 bar, oil and water-free

Installed electrical power: approx. 5 kW

Voltage: 3x 400V, 50Hz, 3-phase

Control voltage: 230V, 50Hz / 24V DC

Longitudinal Slitting and Length Measuring Unit :

Manufacturer: Suchy

Machine number: 273/05

Year of manufacture: 01/2006

Weight: 250 kg

CE conformity declaration available

Up to 8 circular slitting knives can be operated via a central control panel

Individual web width settings are adjusted manually

Incremental Winder :

CE conformity declaration available

Winding roller diameter: 350 mm

Minimum winding diameter: 3-inch cardboard core

Maximum winding diameter: 1,500 mm

Installed power: 5 kW

Edge Waste Recycler:

Electrical supply by Hepp-Schwamborn, Moenchengladbach

Nominal voltage: 400V, 3/PEN

Frequency: 50 Hz

Short-circuit breaking capacity: 10 kA

Full-load current: 25 A

Maximum fuse: 32 A

Control voltage: 24V DC

Description: Picks up edge trim from the slitting process, shreds it, and returns the shredded fibers via a blower to the feed shaft for recycling into the production process.

9. X-Ray Measurement Device

Manufacturer: Protagon

System type: Quality Control System, X-Ray 5kV, CLP-c

Installed power: 1.5 kVA

Operating voltage: 230V AC, 1-phase, 50Hz

Auxiliary voltage: 24V DC

Description: The FLG/thickness measurement system is used for quality control and evaluation of uniform basis weight and thickness of the produced material web. The sensor is mounted in a scanning frame that traverses across the web. Measurements are taken online and without contact. Cross-machine profiles and machine-direction trends are displayed. The system controls the Autefa cross-lapper via closed-loop feedback based on the measured basis weight.

Additional: Machine Display Console (Maschinenanzeigetableau)

Central display console with individual operator panels for: Protagon measurement system, Needleloom, Cross-Lapper (Leger), and Card (Krempel).

PRE-MIX UNIT 5

The pre-mix unit is a fiber bale opening and pre-blending system. It consists of three components listed below.

1. Feed Table

Roller conveyor table for feeding fiber bales to the bale opener

Overall combined feed table length: 2x 3,100 mm (6,200 mm total)

Feed table width: 1,600 mm

Table height at bale opener entry: approx. 1,250 mm

2. Bale Opener

Overall machine width (opener section): approx. 1,800 mm (inner opening width approx. 1,585 mm)

Machine height: approx. 3,075 mm

Machine depth (opener body): approx. 2,450 mm

Overall installation footprint with feed table: approx. 3,750 x 3,950 mm

Description: Pre-opening machine for opening pressed fiber bales and uniformly feeding downstream machines. Suitable for natural and synthetic fiber bales.

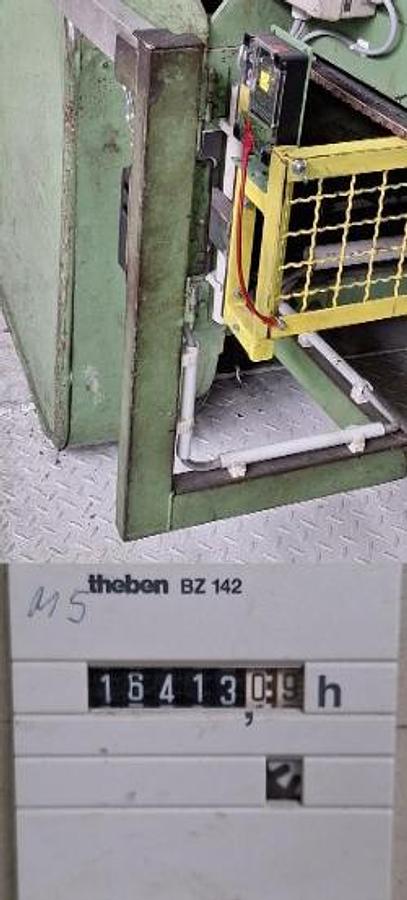

3. Card Wolf

Manufacturer: Societe Anonyme des Ateliers Houget Duesberg Bosson

Model: 4260

Year of manufacture: 1972

Maximum working width: 1,500 mm

Configuration:

1 feed table

2 feed rollers

1 main cylinder with 3 worker/stripper pairs

1 output worker

Control cabinet dimensions (W/D/H): 1,600 mm x 600 mm x 2,200 mm

Operating hours recorded on counter: approx. 16,413 hours

Find more here - https://www.ucymachines.com/

Contact us at - sales@ucymachines.com

Specifications

| Manufacturer | - |

| Model | Complete Used Nonwoven Production Plant for Sale - Needlepunch Line with Fiber Opening, Carding, Lapping, Needling and Winding |

| Condition | Used |

| Stock Number | 757557 |