2021 Spinner VC 850

2021 Spinner VC 850

Location:Dortmund, Germany

Description

Manufacturer: Spinner

Model: VC 850

Year of Manufacture: 2021

Operating hours:

Control unit on: 3891 hours

Machine on: 3698 hours

Program duration: 727 hours

Spindle runtime: 702 hours

Axis runtime: 637 hours

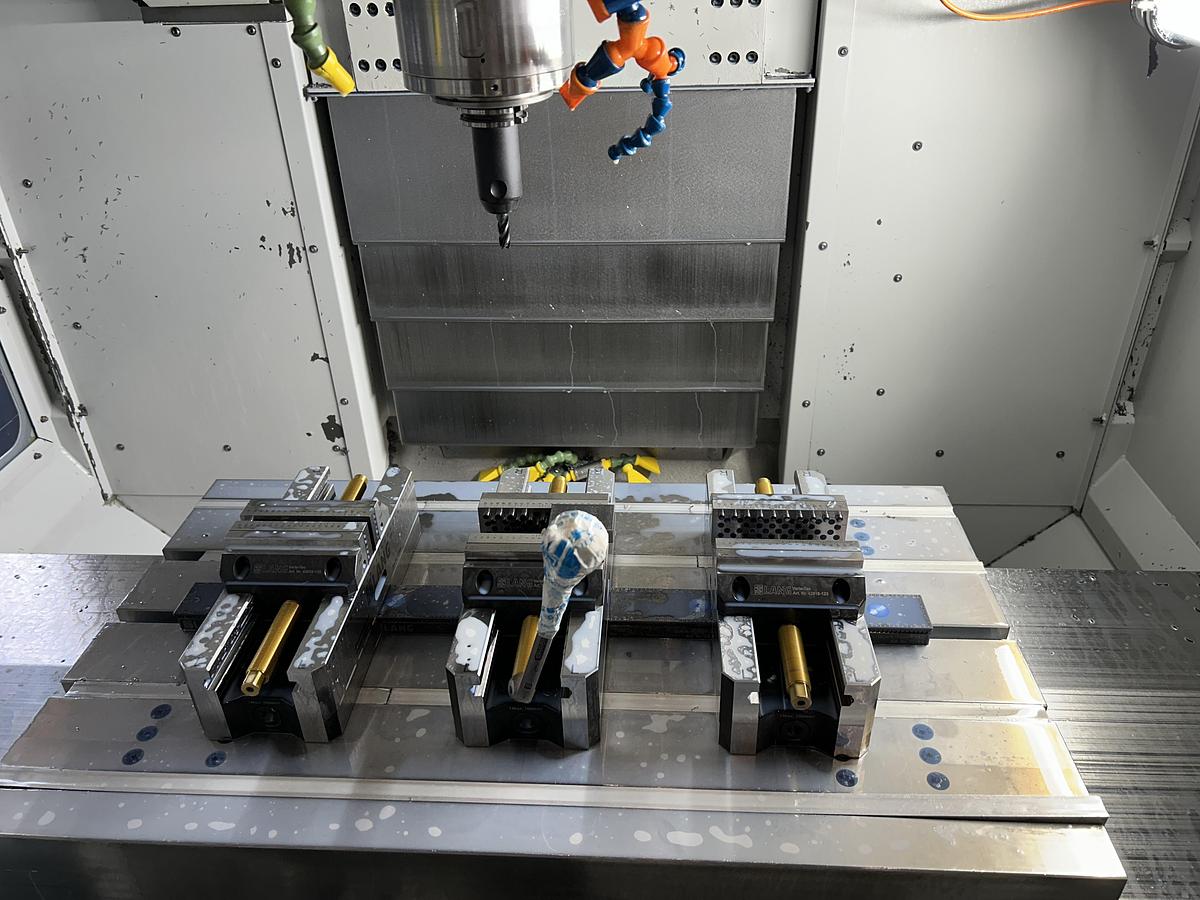

SPINNER VC850 vertical machining center with Heidenhain control

The SPINNER VC850 is a compact, high-performance 3-axis machining center for precision milling operations in tool, mold, and machine manufacturing. Its robust construction, high dynamics, and proven Heidenhain control system offer an excellent combination of accuracy, reliability, and ease of operation.

Technical features

- Travel paths:

- X-axis: 850 mm

- Y-axis: 510 mm

- Z-axis: 510 mm

- Steering:

- Heidenhain TNC 620 / TNC 640 (depending on the version)

- Intuitive operation, dialog programming, 3D simulation graphics, teach-in function

- Spindle:

- Speed: up to 12,000 min⁻¹ (optional 15,000 min⁻¹ )

- Spindle taper: SK 40

- Direct drive for smooth running and precision

- Tool magazine:

- 30 tool stations

- Automatic tool change with fast changeover time

- Feed rates:

- Rapid traverse: up to 36 m/min

- Working feed rate: up to 15 m/min

- Table size:

- approx. 1,000 × 510 mm

- Maximum table load: approx. 600 kg

Functional description

The SPINNER VC850 machining center is designed for precise 3-axis milling operations. Thanks to its solid cast iron construction, it offers high stability and vibration damping, enabling excellent surface finishes even with demanding materials (e.g., steel, aluminum, cast iron, plastic).

The Heidenhain control system allows for simple and quick programming directly at the machine – ideal for individual parts, small batches, or toolmaking. The machine features precise linear guides, automatic central lubrication, a high-performance coolant system, and an integrated chip conveyor, ensuring reliable and clean long-term machining.

This machine does not have a measuring probe.

Thanks to its compact design, the VC850 requires only a small footprint and can be easily integrated into existing production environments.

Advantages at a glance

- Compact design with a large workspace

- Precise Heidenhain control for easy operation

- High spindle performance and dynamics

- Integrated coolant system and chip conveyor

- Ideal for toolmaking, mechanical engineering, small series production and individual parts

- Maintenance-friendly, robust design “Made in Germany”

- Optionally automatable (e.g. with pallet changer or robot loading)

Typical areas of application

- Precision components in mechanical and tool engineering

- Aluminum and steel processing

- Mold and fixture construction

- Prototype production

- Training and experimental workshops

Optional accessories

- Axis (rotary table)

- Coolant system (present)

- Chip conveyor (present)

- Oil mist extraction

- Tool measurement / measuring probe (not available on this machine)

Find more here - https://www.ucymachines.com/

Contact us at - sales@ucymachines.com

Specifications

| Manufacturer | Spinner |

| Model | VC 850 |

| Year | 2021 |

| Condition | Used |

| Stock Number | 757238 |